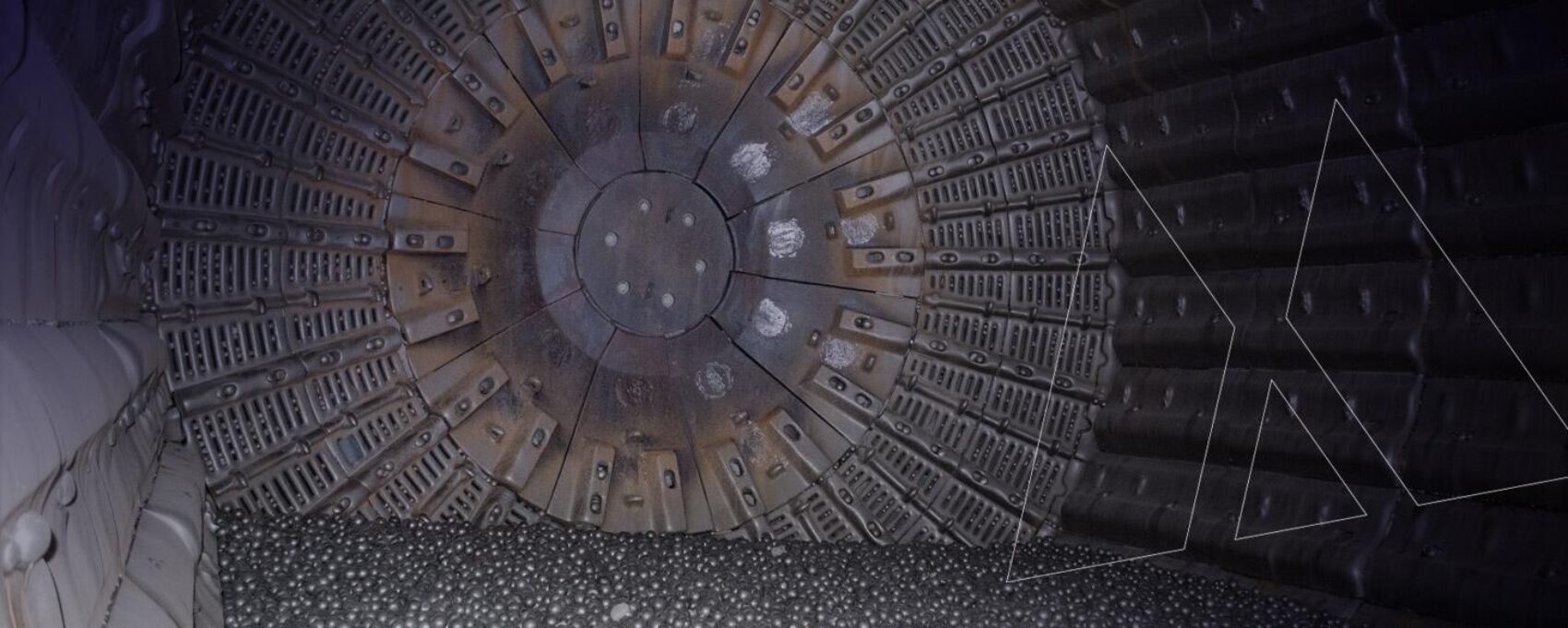

Designed for discharge efficiency

The role of the grate is to allow the discharge of the material ground in the mill via the slots. With our range of alloys and design experience we can offer the longest possible lifetime with the optimal grinding efficiency.

The design of the grates will depend on:

- Drilling pattern

- Mill speed (rpm)

- Maximum grinding media diameter (mm)

- Grinding media filling degree (%)

- Throughput (open area & cm²/t)

- Presence of pebble