Maintain grinding efficiency at the max!

Regular ball sorting is a must to maintain tube mill efficiencies and avoid losses of up to 10-20%. The quality of the sorting and its frequency are both critical.

- 1st chamber: balls below a specific dimension have to be rejected to avoid overloading or even back spilling effects. Sorting to repeat every 1-2 years

- 2nd chamber: the balls gradation has to be respected to avoid a too fine ball charge which could lose permeability and clog the outlet grates slots. Sorting to repeat every 2-4 years

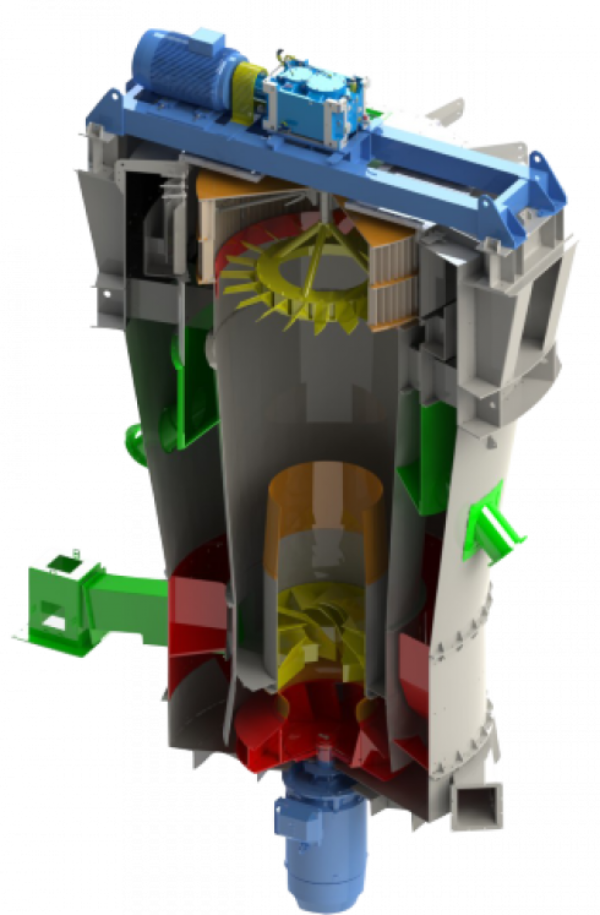

Magotteaux ball sorter allows achieving the above in a fast and safe manner, requiring little manpower.