Specifications

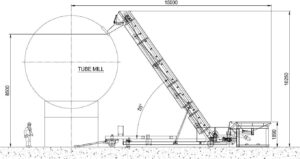

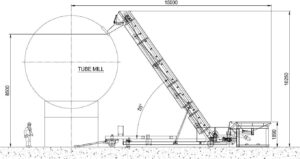

The ball loading machine consist of following major components

- A ball hopper equipped with an electromagnetic vibrating feeder

- A special belt conveyor with adjustable slope

- An adjustable discharge chute at the upper end of the conveyor

- A control unit

- Two hydraulic jacks

- Four independent wheels for precise positionin

The slope of the conveyor is adjusted by using two hydraulic actuators.

The discharge chute at the upper side can be adjusted in all directions i.e. up/down and right/left for easy positioning of the loader in respect to mill manhole entry.

Mechanical specifications

|

Ball loader H65 |

Ball loader H85 |

| Max lifting height |

6500 mm |

8500 mm |

| Belt width |

600 mm |

0.8 m/s |

| Belt speed |

0.8 m/s |

0.8 m/s |

| Weight |

5.7t |

6.5t |

| Ball loading capacity |

15 tph to 25 tph for a diameter from 10 to 100 mm |

15 tph to 25 tph for a diameter from 10 to 100 mm |