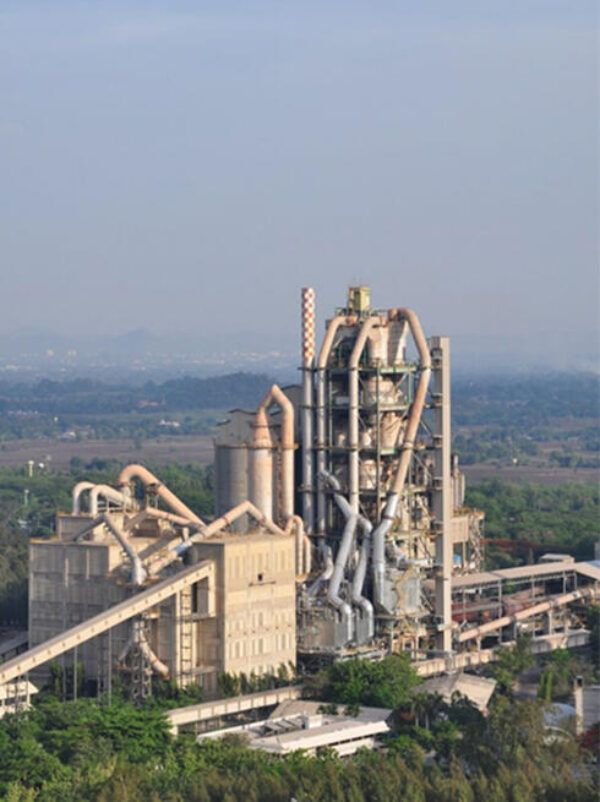

Expect measurable productivity, energy & safety improvements!

Our focus: reducing energy consumption and optimizing performance!

Mill liners need to protect the mill shell from damages due to wear and transmit the energy from the rotating mill to the ball charge.

The rules that guide the design of a liner depend on the grinding mechanisms required for the specific mill. They can be classified either as impact/cataracting for very coarse to coarse grinding, cascading for coarse to medium grinding or attrition for medium to fine grinding.

In any case the design of a liner is a compromise between lifetime and grinding efficiency.

Our focus: reducing energy consumption and optimizing performance!

Our multibusiness experience in crushing benefits to our customers as we offer safer and technology proven solutions to all applications.

The recent trend to increase the usage of abrasive and corrosive alternative fuels has let us to develop new solutions.

These solutions optimize wear parts lifetime and process efficiency, reduce energy consumption, ensure safe handling, reduce inventory… leading to significant savings.