Magotteaux Expand rollers as a game changer in the Aggregates Industry

Hartsteinwerk Kitzbühel, a customer of Magotteaux, faced significant challenges with his Vertical Roller Mill (VRM) wear parts in his ultrafine grinding process for fertilizer production.

Background

Hartsteinwerk Kitzbühel, a customer of Magotteaux, faced significant challenges with his Vertical Roller Mill (VRM) wear parts in his ultrafine grinding process for fertilizer production. The frequent high wear rate led to time-consuming maintenance, requiring three people and two full days to rebuild the rollers. The client, accustomed to hardfacing, was reluctant to switch to an MMC solution, claiming it would be brittle.

Additionally, the customer complained about the wear control system provided by the OEM, describing it as quite archaic. Consequently, they sought Magotteaux‘s assistance for a more durable and less labor- intensive solution to measure the wear rate.

Solution

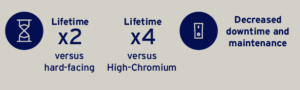

To reassure the customer, Magotteaux committed to providing a full year‘s supply in exchange for a flat fee equivalent to the annual cost of wear parts for this mill. This agreement assured the customer that there would be no additional costs. These longer-lasting castings are designed for vertical mills, offering superior wear resistance and reduced maintenance downtime. Magotteaux aimed to address the customer‘s concerns about durability and breakage, showcasing the reliability and cost-effectiveness of the Expand rollers.

Results

After 2000 hours of operation, the first set of Expand rollers was dismantled because the customer needed to access other parts of the mill for maintenance. The rollers could have definitely reached the 2400-hour target. The increased lifespan improved maintenance efficiency and safety by eliminating the downtime required to replace the rollers, which typically necessitated at least two to three shutdowns with hardfacing.

This also resulted in shorter or no mill stops, allowing for higher mill availability and extended production periods. Additionally, Magotteaux‘s visual wear control system, featuring wear patches in the ceramic core, greatly improved wear monitoring. By exchanging photos with Magotteaux, the client achieved excellent visual control over wear and the remaining lifetime of the production, addressing a key concern. As a result, the customer was extremely satisfied and decided to continue using our Expand rollers in the future. The repeated and ongoing orders from the customer to Magotteaux are impressive proof of their satisfaction with the proposed Expand solution.