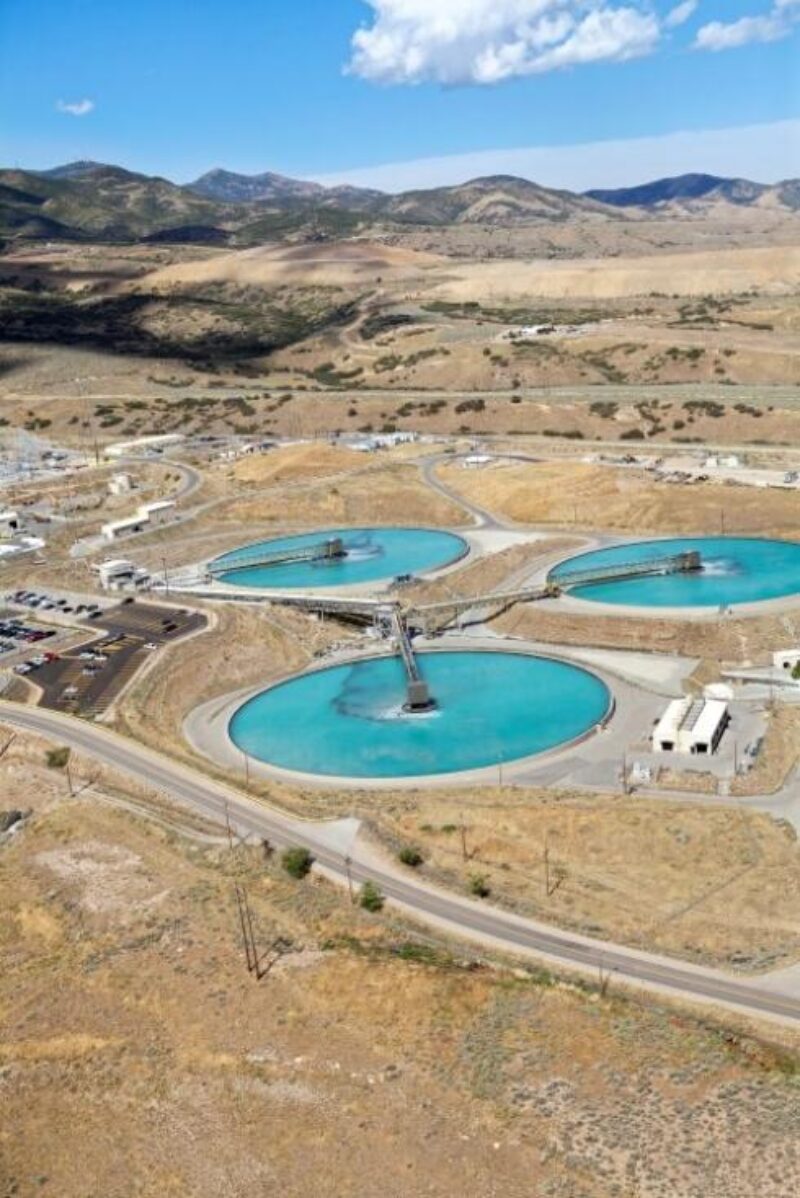

Copper mining – Secured recovery

Our client was examining ways of reducing its operating costs and approached Magotteaux to determine if a lower chrome ball could be used in its ball mill to reduce grinding media costs.

Client request

Our client was examining ways to decrease their grinding media costs.

Proposal

The grinding media cost was reduced by the equivalent of 200,000 USD/year by switching to a lower cost cast grinding ball. The customer indicated that should the plant suffer a loss in copper recovery they would revert to the initial alloy.

Monitoring

To determine if changes in the chemistry were induced and their potential adverse effects on copper recovery, examination of the pulp chemical data collected occurred on a fortnightly basis.

Result

The statistical analysis showed clearly that the copper recovery had decreased by at least 1.3 % with the change in grinding media alloy. This represented a gross loss in revenue of 9 million USD/year.

The site immediately requested that Magotteaux supply grinding media with the initial alloy.